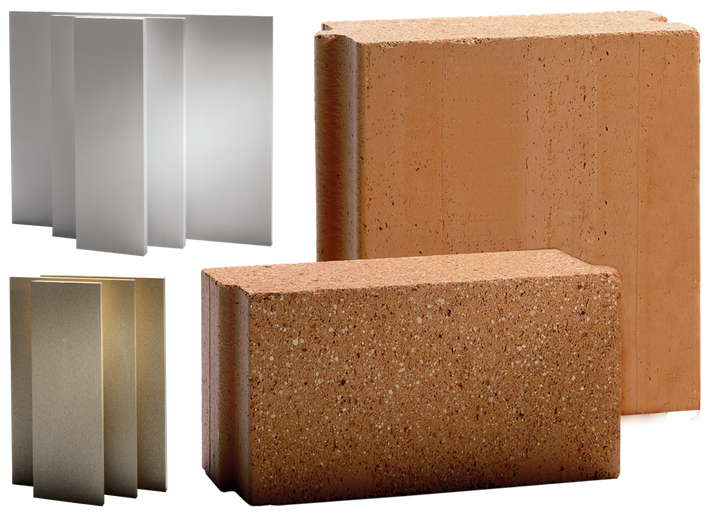

Skamol produces and markets insulation systems based on the three key raw materials calcium silicate, vermiculite and moler. The system portfolio spans bricks and blocks, insulation boards and fire protection boards which drives health-, safety- and energy preserving benefits for customers and end-users around the world.

Skamol has selected the following UN Sustainable Development Goals to which we have an opportunity to contribute:

Goal 9 – Build resilient infrastructure, promote inclusive and sustainable industrialization and foster innovation

Opportunity to make production process more efficient and increase resource-efficiency by adopting cleaner and more environmentally friendly industrial processes.

Goal 12 – Ensure sustainable consumption and production patterns

Efficient use of natural resources and reduce waste generation through prevention, reduction, recycling and reuse.

Goal 15 – Protect, restore and promote sustainable use of terrestrial ecosystems, sustainably manage forests, combat desertification, and halt and reverse land degradation and halt biodiversity loss

Restore terrestrial land.

As a global wholesaler, Alumeco offers a wide range of metals, so you can buy everything in one place. We offer both standardized and customized solutions, and we are ready to support you at every step. As your preferred metal partner, we ensure the best guidance, solution and quality every time.

In Alumeco we have chosen to work with four UN Global Goals:

Goal 7 – Affordable and clean energy

Our goal is to use 100% renewable energy in 2040 by lowering our demand for energy and producing solar power on our own properties.

Goal 8 – Decent work and economic growth

To ensure a safe and healthy work environment in Alumeco Group, we are in the process of being ISO 45001 certified at our four major production and warehouse facilities.

Goal 12 – Responsible consumption and production

To reduce the production of new (primary) aluminium, we are reducing our own scrap production to utilise the already existing aluminium even more and increasing the availability of recycled aluminium products (RecycAl). We also offer GreenAl, an aluminium product produced using renewable energy, which has a significantly lower carbon footprint than traditional primary aluminium.

Goal 13 – Climate action

Our goal is to reduce our carbon footprint (scope 1+2) by 80% by 2040. We will reach this goal by reducing our own emissions and investing in climate offset projects. So far, we have reduced our footprint by 18% by reducing our own emissions.

At Aluflam, we are experts in the area of fire protection made from glass and aluminium. We offer a wide range of fire proof constructions in the fire category E15 to EI 120. For example facades, windows, doors, sliding doors, skylights and glass ceilings.

Our design varies from standard formations to complicated special design solutions, often in cooperation with architects. We continuously develop new products and due to our new Extrusion factory in Lithuania equipped with modern painting facilities, we can offer custom-made solutions.

Aluflam has for many years also been supplier for off shore establishments and cruise ferries, where we are working together with shipowners and architects. Aluflam has several branches including in the US, Australia, Lithuania and Egypt.

Aluflam focuses in particular on UN sustainable development goals:

Goal number 12: Responsible Consumption and Production

At Aluflam, we have chosen aluminium as our primary material, because the material can be reused over and over again – only requiring 5% of the energy needed for producing the raw material. In addition, aluminium is maintenance free. Aluminium reacts with the oxygen in the air and forms a protective oxite coating which makes it resistant to corrosion. This means less maintenance and replacements compared to metals like iron or steel. Less maintenance and less replacements are good news for both the environment and the total budget for any construction.

Great ambitions lead to success. With roots dating back to 1913 A/S HAI Horsens is a rapidly growing company. HAI are currently the largest surface treatment company for aluminum in Northern Europe and specialize in Europe’s broadest range of aluminum finishes. Our services include wet coating, anodizing for both in- and outdoor use, hard anodizing and passivation, together with a big variety of pre-treatments and finishes.

We engage in confident partnerships with our customers ranging from product development to the planning and execution of complex and efficient big scale production setups. Our brand new state of the art wet painting facility offers a big variety of specialty coatings which can be applied both manually and completely automatic by robots.

Commitment to sustainability and uncompromising quality

At HAI, we prioritize both sustainability and quality in everything we do. Since 2021, we have been ISO 14001 certified, a testament to our commitment to environmental management and sustainability. This certification guides us in reducing our environmental impact and aligns our efforts with the United Nations’ Sustainable Development Goals.

Our focus on quality is underscored by our ISO 9001 certification, which we’ve held since 1993. This standard is the backbone of our operations, ensuring continuous improvement, process optimization, and exceptional surface treatments. Our advanced testing facilities, including corrosion and salt spray tests, lightfastness evaluations, and precise µm measurements, confirm that our finishes are durable and reliable, meeting the highest industry standards.

Bending Technology Denmark A/S, Formerly known as Gustav Østergaards Maskinfabrik A S, is Denmark’s oldest and most experienced Rolling company specialized in rolling and bending of aluminum profiles.

At Bending Technology Denmark A / S, we focus heavily on our many customers at home and abroad, with the aim of building sustainable long-term relationships. We work widely with all types of rolled aluminum profiles as well as other metal profiles.

We deliver a high variety of profiles into the European industry. Amongst them are Rehab Equipment, health care, exclusive constructions, parts for machinery, parts for wind/energy Sectors, Transportation, Lighting systems. Our knowledge within our field, and a commitment to building relations with our customers gives us a strong standpoint, in solving our customer’s needs. We love to be challenged and are well known for solving highly complex bending projects.

We can deliver the suitable documentation for any project, to make sure that the quality of deliveries is secured.

We work with our own developed rolling concept and work every day to realize our mission statement: BENDING BEYOND LIMITS.

Sjølund is a world leading company specialized in aluminum and steel section bending. We have more than 80 years of experience providing bending solutions for all industries. We are driven by curiosity, ideas and ambitions.

We can provide several different state-of-the-art metal solutions, either alone or in combination with bending, machining, welding, assembly and surface treatment.

We specialized in bending steel and aluminum. Our goal is clear: We want to be the world leader in the market. Together with our dedicated customers worldwide, we work tirelessly towards this goal. Our production facilities in Denmark and China are the largest and modern. In China, we have established an up-to-date and modern production facility to service our customers in this fast-growing APAC market, from a local platform. We also work together with competent engineers and architects to solve specific complex tasks. A long list of references from around the world can prove that.

Vision

THE PARTNER OF CHOICE FOR A SUSTAINABLE FUTURE

We work closely with our stakeholders to shape a sustainable future, delivering optimum value and customer experience.

DISUBCO is a one stop company, Supplying products of aluminum, titanium, stainless steel, and steel. Our experience, know-how and big selection of partners makes us capable of transforming our customers ideas to reality. We provide full supply chain solutions with everything from purchasing the raw materials, casting, extrusion, CNC-machining, surface treatment, assembly, engraving, quality assurance together with packing and logistics services.

At DISUBCO we take pride in helping our customers reaching their goals and product expectations and we are always ready to guide our costumers select and surface finish.

Driving innovation and sustainable production solutions

DISUBCO’s customers are often companies with focus on innovation and development. We contribute with years of experience and our expertise in the production of our customers products, fulfilling their ideas by putting them in practice. When DISUBCO helps with the production of customers products, it releases its own resources for more development and sales, which results in more innovation and growth.

DISUBCO has lately helped more customers get their products produced in Europe again, instead of China. Together with our modern partners, we have been able to ensure that customers’ products can be produced at the same final price. This helps to reduce the transport of the products and lower the CO2 consumption per product.

We are your global turnkey supplier of tailor-made metal components. We help you produce smarter – which benefits both the environment and your profitability.

Get a more sustainable solution

With innovative design and the widest range of metal forming processes on the market, we effectively reduce your waste material and carbon footprint. We help you optimizing your production, so you can operate both smarter and greener.

On request, we can deliver a report on your steel product’s CO2 footprint – scope 1, 2 and 3.

INNOVATIVE COIL COATING SINCE 1973

Since 1973 Metalcolour has been highly committed to and focused on delivering value to clients in defined segments. Metalcolour’s size and production set up, makes it possible to offer a superior service and we are setting a market standard for fast delivery, by employing a flexible and 100% customer focused production and service approach.

Utilizing our resources in our specialized production and working with carefully selected co-producers, we are able to provide innovative solutions that reduce cost and create value to our clients. All details in our production line, raw materials and logistical services are carefully monitored in order to ensure the highest quality in products and services.

Metalcolour has a strong European presence, now strengthened by Metalcolour ASIA with its production line and office in Singapore.

COATED STEEL AND COATED ALUMINIUM

Taking the step from piece coating to using pre-coated metal in your production process, will save you both time and money and even shorten your lead times. Metalcolour Technical Coating is a highly specialized product range offering customized solutions in coil coating of numerous metal substrates, e.g. coated steel or coated aluminum, with own developed or customer specified coatings, primers and binders.

BENEFITS

- Consistent and uniform quality

- Industrialisation

- Cost cutting

- Allowing for new technologies

VALUE BASED CUSTOMIZATION

The economies of scale in our production lines, combined with our solutions for logistics and planning are the main factors to bring down cost per unit. Metalcolour has 50 years of experience in coating of sheet metal and can offer valuable input in designing new solutions and processes for your company. Our large scale production facilities enable possibilities of industrialization of otherwise costly and more manual labor intensive stages of production, leading to significant reductions in overall costs.

A global supplier of high-end machined components

Multicut delivers advanced machined components to the most demanding industrial production sectors in the world: Greentech, the energy sector, defense and aerospace applications, and to any industry that requires supreme standards of precision and workmanship.

The machinery we use is the same as everyone else’s (as long as it is the best). But our ingenuity, determination, and will to succeed are not. And we always find ways to deliver components that are uniform and of the highest possible standard of quality.

Security in supply and scalability

To Multicut, delivering and guaranteeing security in supply means that the entire production set-up is customized and designed for 100% automated manufacturing, ensuring on-time delivery every single time. Our ability to deliver security in supply further makes it possible for us to do a production ramp-up without any obstacles. Security in supply has become a commodity in today’s industry and is essential to all businesses to maintain a seamless and streamlined supply chain.

Multicut. Cutting edge manufacturing solutions.

Nymark & Fogh Teknik ApS is a highly experienced and reliable partner in the manufacturing of aluminum components, potentially with subsequent surface treatment. We are happy to offer a total solution that meets our customers’ needs.

We can offer an active role as a sparring partner when it comes to consulting, prototype development, or in series production and optimization of aluminum components.

Nymark & Fogh is an order-producing machine factory that delivers total solutions

Our core competencies are chip-removing CNC machining on flexible CNC machines, as well as cutting aluminum profiles on automatic saws, operated by very competent and dedicated employees. We can adapt to any customer’s needs with other stages in the value chain through a large network.

We produce everything from single pieces to several thousand pieces and develop prototypes in close cooperation with our customers. At Nymark & Fogh Teknik ApS, we emphasize extreme flexibility, development of new products, and techniques.

About Onestopalu

If you wish to establish contact to some of the most innovative and competitive aluminium product developers and suppliers from Denmark then you should visit this web-site and find inspiration for your future development. You can also just visit the Danish Pavilion at the Aluminium 2024 fair on October 8-10 in Düsseldorf, Germany.

Contact us

Please do not hesitate to contact us for further information.